What happens when innovation meets tradition?

Modern trousers hand-crafted to perfection and made responsibly in Europe.

MEYER – always one step ahead.

Our family business was founded in 1960 in Oberbergischen and is now the leading European specialist for men's trousers. We combine hand-crafted tradition with innovative thinking and progressive action. The modern fits, unique details and outstanding fabrics for which our trousers are known are FAIR & sustainably produced in Europe.

Trousers from a good home.

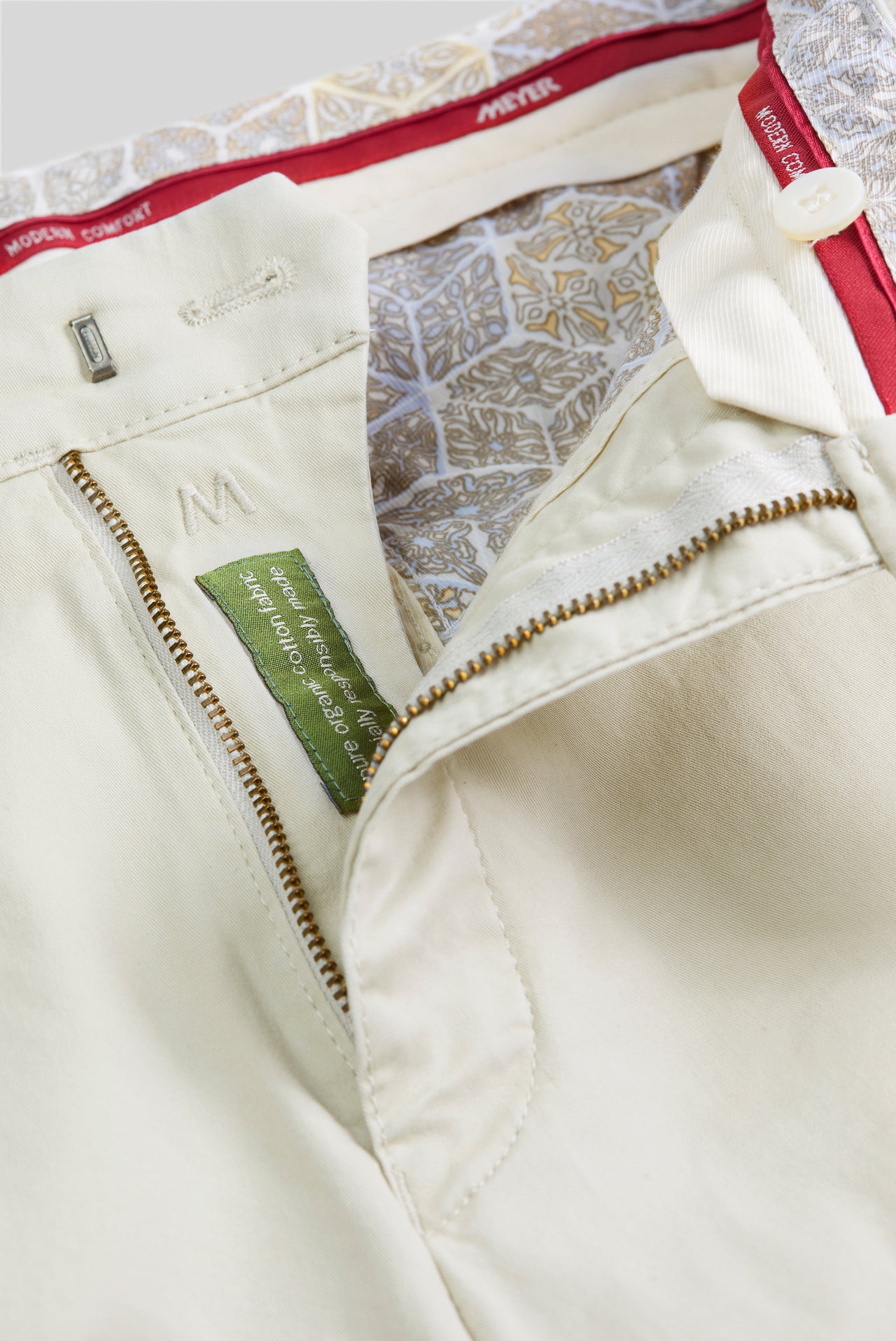

Our trousers are made at our own European production facilities. This allows us to observe the most up-to-date social and environmental standards and guarantees exceptional quality through regular inspections after each individual production step. Since the '90s, our production facilities have been located in the Romanian city of Târgu Secuiesc in Transylvania, a place that is home to a centuries-old tradition of craftsmanship. Outstanding machines from JUKI, Pfaff and Dürkopp Adler ensure optimum quality owing to the high seam quality. Furthermore, many of the production steps are done by hand – inspired by the art of bespoke tailoring. The sophisticated contour waistband, the turning over of the pocket lining and the decorative stitching on the seat pockets are examples of this. The loops for the belts and the buttons with a shank are also attached by hand.

Natural lasts longest – our raw materials

We use primarily natural raw materials to make our trousers. The most important of these is cotton. In 2020, we switched completely to pure organic cotton. We also rely entirely on nature's unrivalled capabilities for most of our other raw materials, too. These fibres have impressive characteristics. Synthetic fibres are only used to give the trousers extra stretch or special features. They are of a high quality and are recycled, where possible.

Quality from the start – our fabrics & fixings

We work intensively with European fabric suppliers on the new collections. We have also set out the MEYER quality requirements in a product passport and these are continually checked against the latest standards. Only fabrics that are proven to comply are allowed to be processed further. The majority of our "fixings" such as buttons, yarns and zips also come from Europe and are often made from natural materials or are recycled.

The perfect fits do exist.

Depending on their texture, fabrics react differently to the washing process. Therefore, each fabric has its own shrinkage value. Multiple tests carried out at our own production facilities guarantee that the perfectly created fits produced by our design centres retain their shape permanently.

The 100 pieces of a pair of trousers

Our trousers are made from around sixty cut pieces of cloth, around 380 metres of yarn and several "fixings". Many of the required production steps are done by hand. Inspired by the art of bespoke tailoring, they have a semi-sartorial finish.

Less talk – more action. Social commitment.

As a socially committed family business, we actively contribute to improving living conditions. We are doing pioneering work in this time – in the fashion industry. As a company, we are involved in numerous campaigns and projects both locally and in Romania, where our production facilities are based. We are making a significant contribution and offering support where support is needed – whether that's in the area of health, education or culture.